Bioprocess Systems for Industrial Cell Proliferation

The use of cell cultures has established itself as the basis of production for certain raw materials in many areas. Particularly, fields like Cultivated Meat offer many advantages over conventional production methods. The CellTec team, as the first European system provider, has unique expertise in this area and offers support for every possible aspect of the customer workflow, in addition to implementing complete proliferation processes.

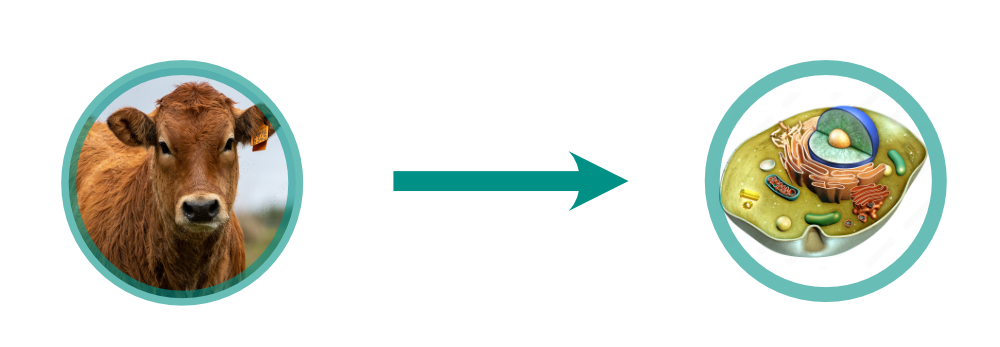

Until now, cell cultures have been primarily used in the pharmaceutical sector, for example, for the production of antibody test systems or the manufacture of certain other proteins. Our proliferation process is based on various patented methods and begins with the gentle biopsy and processing of fresh tissue samples or the removal of already isolated cells from our comprehensive cell bank. Besides selection and proliferation, it also includes the harvesting and preparation of downstream processes into a marketable product.

Steps from Cell to End Product

All procedural steps are designed to be modular, allowing individual methods or subsections to be integrated into other processes. The individual phases typically comprise various components including consultation, bio-engineering, process engineering, and quality assurance.

Our experts thus provide support exactly where our clients currently need it due to available capacities, such as in the selection of cell lines and media, preparation, scaling up, or directly all these points in one package. This enables innovation-oriented companies to accelerate market entry and reduce their own risk.

Customer Needs in Focus

Currently, companies in many sectors are striving to advance ambitious pilot projects in the field of industrial cell cultures. Often, progress here is unsatisfactory, for example, because acceptable reactor sizes and automated processes have hardly been possible until now. Our approach solves both issues. We support companies, for example in the food industry, but also startups and research companies in implementing bioprocesses in this field. Whether they want to implement a complete production process or need robust, high-performance, and quality-assured cell lines or optimized growth media for existing cell production – we provide competent and targeted support.

For example, this can be used:

- To supplement your own capacity constraints,

- When lacking personnel or other capacities,

- For greater implementation speed (time-to-market),

- To minimize risk by eliminating the need for training new employees,

- As support in integrating into overall operational processes.

Diversity of Possible Applications

Our bioprocesses can be tailored for very different areas. Current areas include:

- The production of Cultivated Meat,

- The establishment of transfected cell cultures for production (e.g., proteins and antibody testing systems),

- The realization of cell-based tests in the chemical or cosmetics sectors.

Advantages for the Customer

Our services are beneficial for our clients in various ways:

- Use of our standardized procedures and processes,

- Maximum customization / High flexibility of possible applications,

- Targeted, minimized work steps,

- Scientifically recognized approach (Credibility),

- Later know-how transfer,

- State-of-the-art technology and research,

- Team of specialists from various disciplines,

- Most modern laboratory capacities, e.g., in our central laboratory in Lübeck,

- Comprehensive partner and supplier network,

- Saving money and making their processes faster.

Quality and Certifications

For maximum usability of our development results, our services are oriented towards the latest, recognized scientific and technical methods:

- Ensuring access to current scientific developments through close cooperation with the University of Lübeck and other companies of Bio Deutschland e.V.,

- Own symposium on industrial cell technology,

- Participation in publications,

- Alignment of laboratory processes with common standards,

- Where necessary, documentation required for customer certifications can be provided.

Project Examples

To illustrate practically relevant service packages, some projects with a clearly defined scope are outlined and described below. Depending on the need, further combinations and interfaces are possible.

Biopsy and Cell Isolation

Many projects in the field of industrial cell proliferation require robust and powerful cell lines created from isolated cells:

Our activity includes the following services:

- Selection of the donor animal,

- Determination of biopsy parameters: suitable organ and context (e.g., ear tag),

- Standardization of the biopsy process for reproducible processes,

- Establishment of the preparation method,

- Creation of associated SOPs,

- Development of necessary quality controls (division rates, ingredients).

Long-Living Primary Cultures

In a further procedural step, long-living primary cultures can be developed from the isolated cells. It is important to us that no genetic modifications are made.

- The goal is a division capability of the cell culture of at least 50x,

- Automated cell monitoring, e.g., with a cell scanner,

- Creation of associated SOPs,

- Repeated execution of identical processes for maximum homogeneity between cells,

- Development of necessary quality controls (division rates, substances).

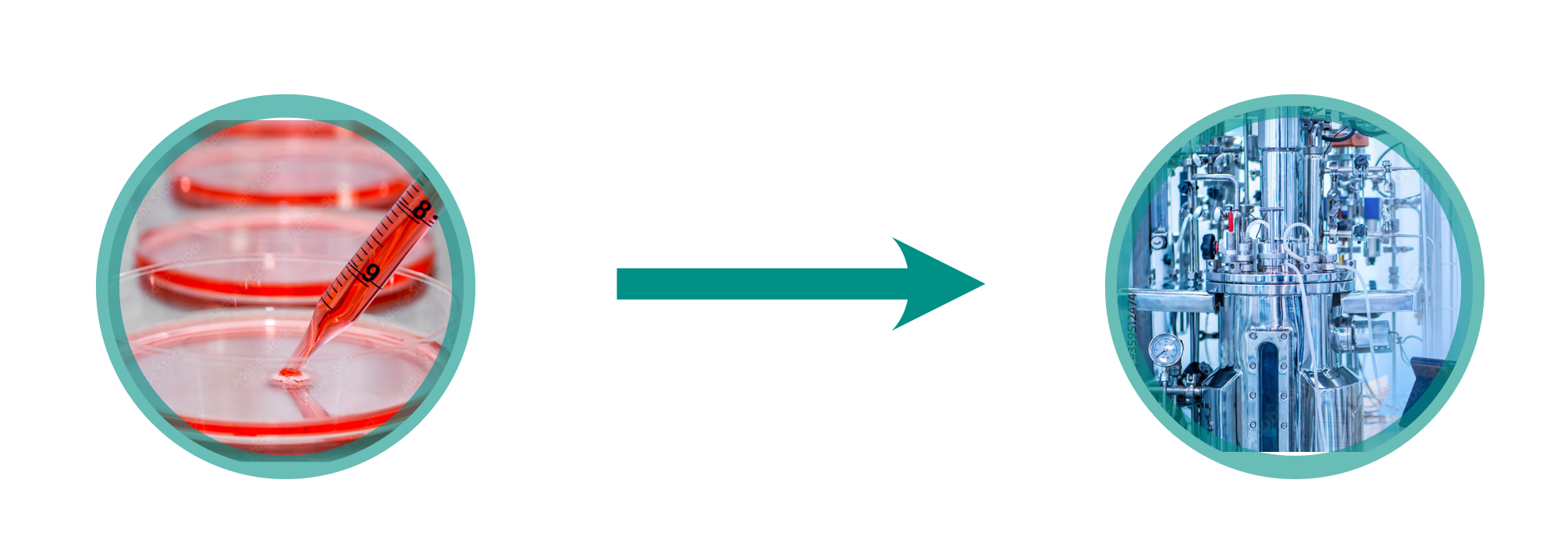

Establishment of Long-Living Primary Cultures to Bioreactor Processes

If proliferation processes are to occur in a bioreactor, the primary cultures must be prepared and adapted to the process accordingly.

- Adaptation of the primary culture to the used bioreactor process,

- Proliferation in the desired method (e.g., suspension, scaffolds, encapsulation),

- Automated cell monitoring (e.g., for metabolites),

- Creation of associated Standard Operating Procedures (SOPs),

- Development of necessary quality controls (division rates, substances).

Further Information

Every application comes with its individual requirements. Do you need targeted and professional support for your cell process projects? Please share your detailed needs with us, so we can create a binding offer for you.

We are happy to provide you with further detailed information about our processes and skills. You can send your inquiries and specifications via email to sales@celltec-systems.com, and we will get back to you promptly.

Contact us.

We will be happy to talk to you.

CellTec Systems GmbH

Osterweide 2c

23562 Lübeck

Germany